Simple assemblies requiring a few helicoils and dowel pins to complex assemblies consisting of multiple machined parts bonded with adhesive and secured with COTS hardware are all well within to scope of G&Z capabilties.

G&Z has extensive experience working with complex BOM's with machined compents and mixes of custom hardware, source control hardware, and COTS hardware.

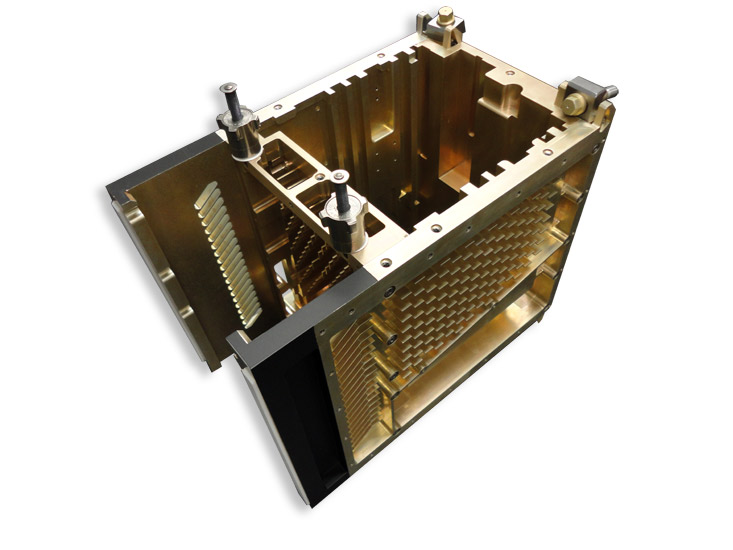

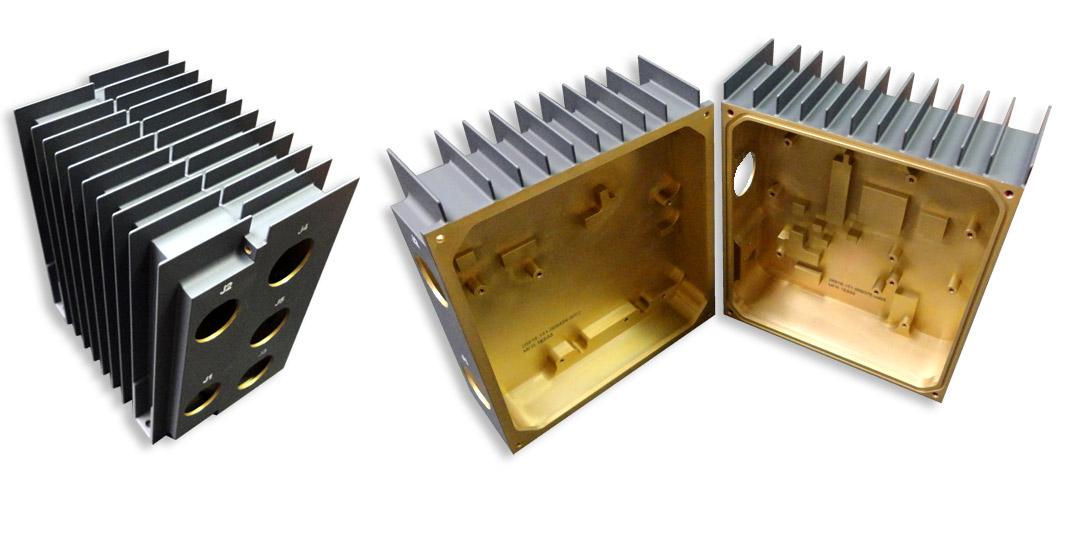

G&Z is a go to source for Electronics Chassis work.

Below are some samples of our Assembly Work:

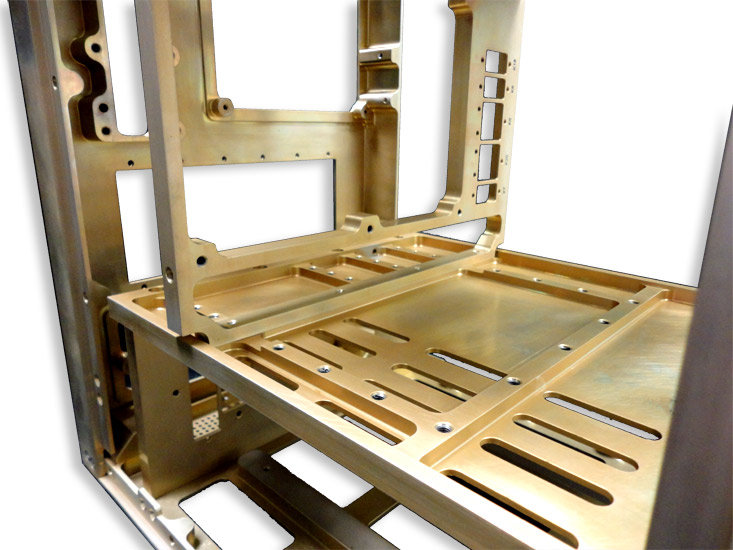

4 Precision Machined Sidewalls, custom hardware, COTS hardware

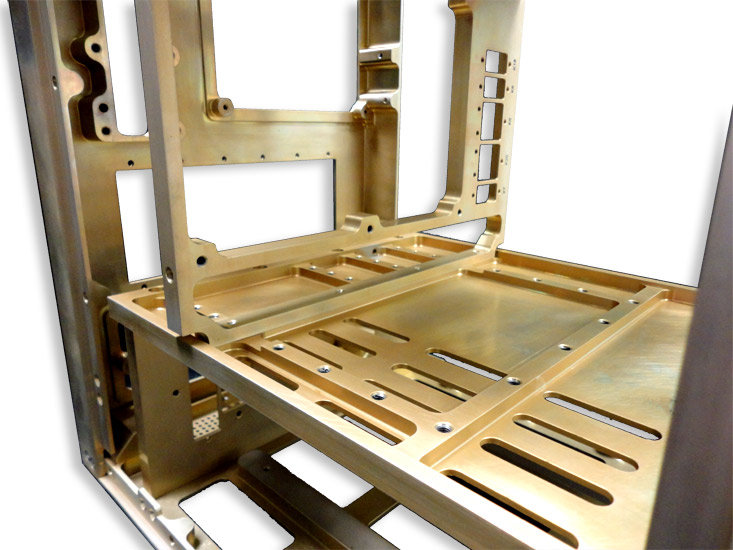

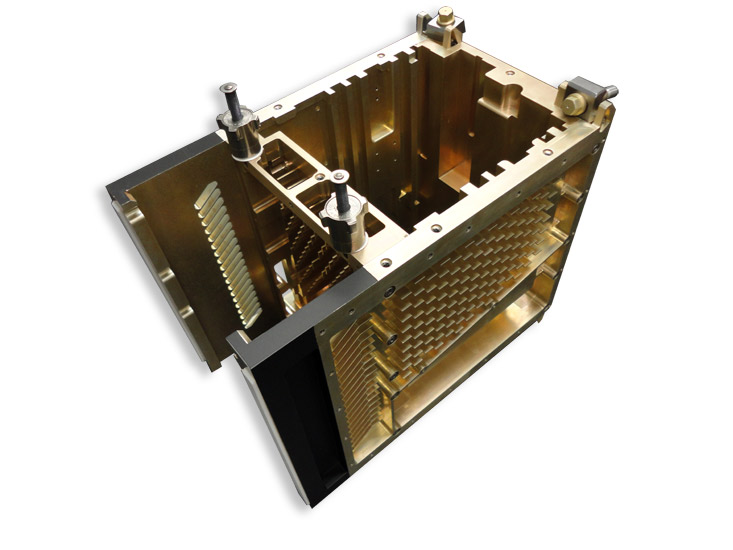

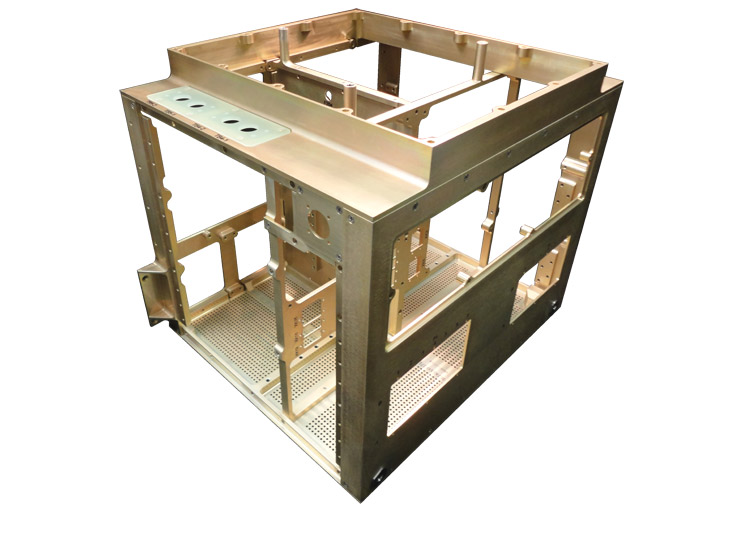

Multiple Machined Components, Sheet Metal, hundreds of COTS hardware components - Approx. 36" x 24" x 15"

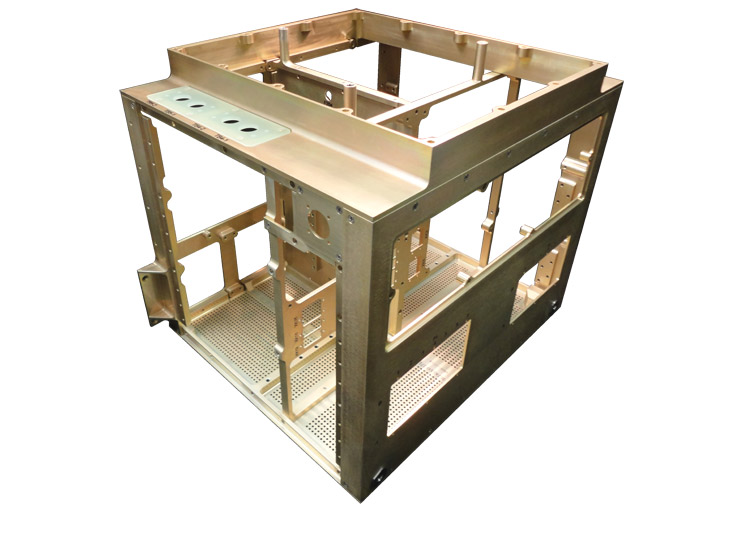

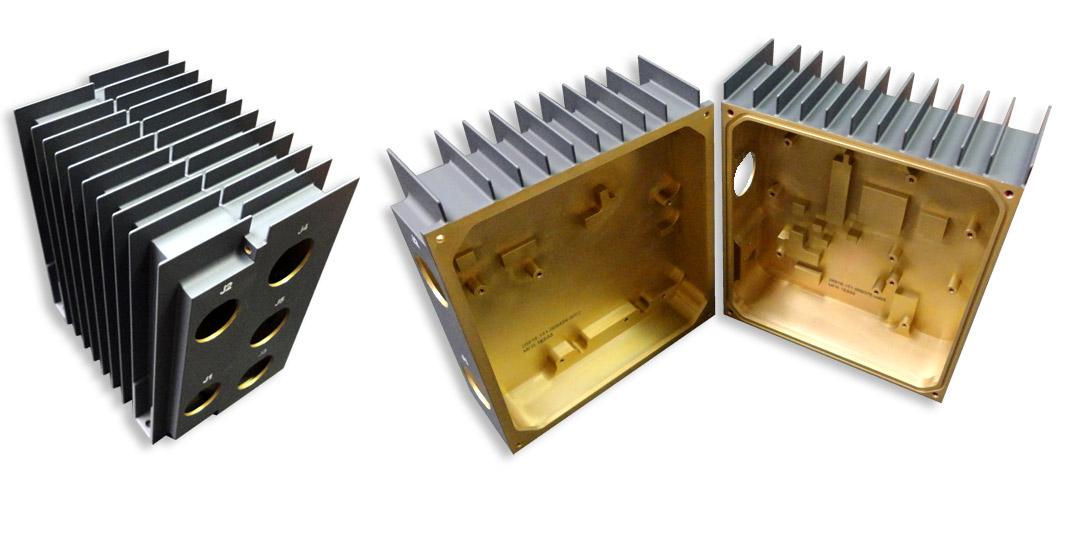

9 Milled Aluminum components assembled with COTS hardware, size 18" x 12" x 12"

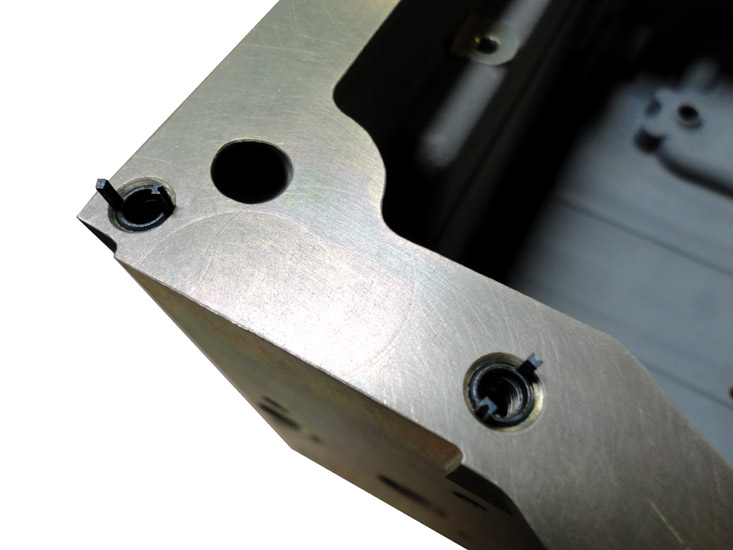

Closeup of Precision Milled plates assembled with COTS hardware

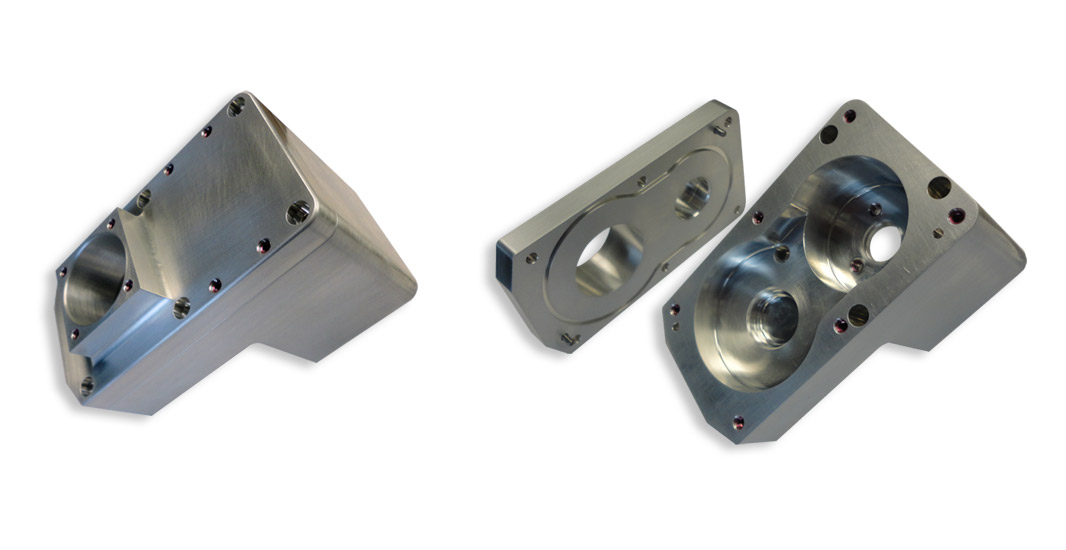

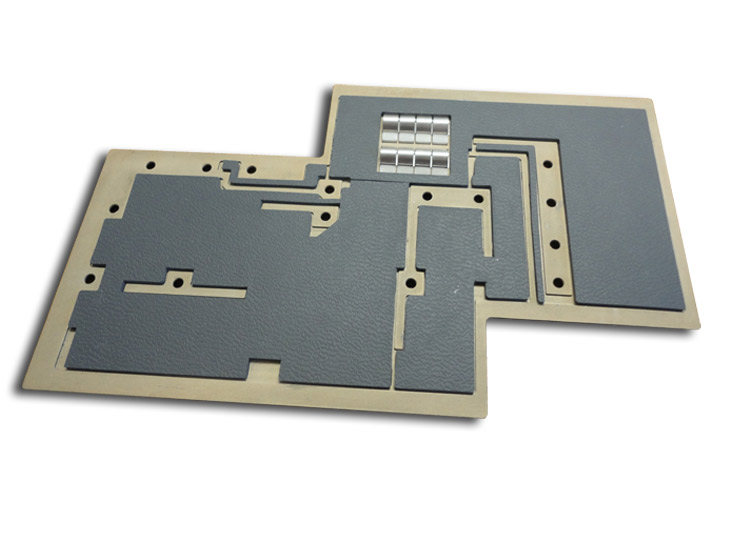

Precision Milled components assembled with COTS hardware

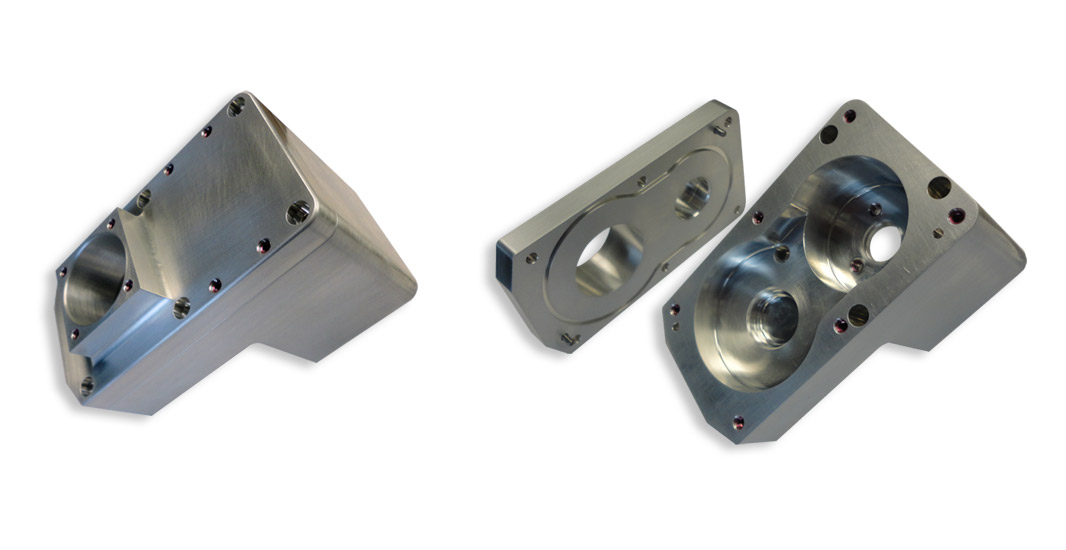

Precision Milled Gear Housing and Cover

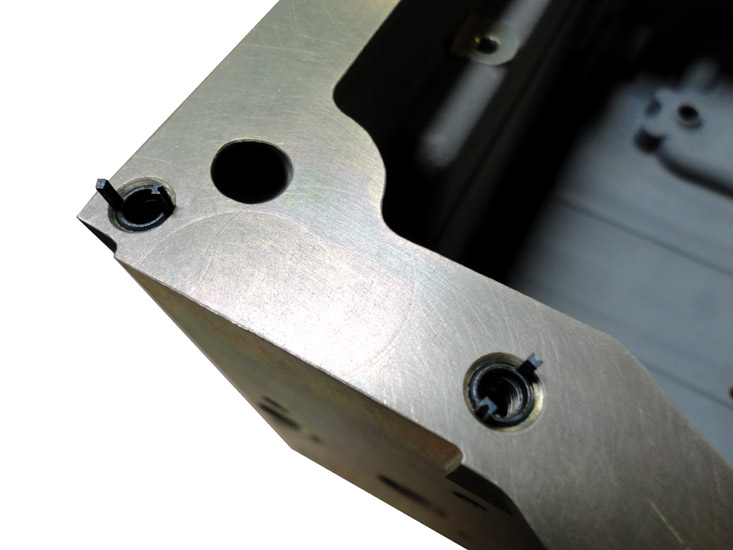

Keyed Inserts prior to seating the locking Keys

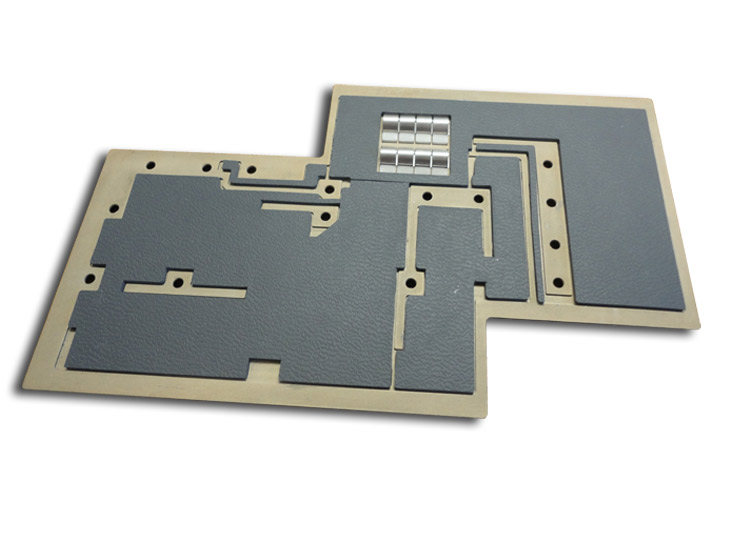

Bonding of EMI Absorbers

Aluminum Milled Chassis halves, assembled with COTS hardware